|

| April 14, 2020 | Volume 16 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

World First: Universal Robots rolls out ActiNav, a super-smart cobot autonomous bin-picking kit

ActiNav from Universal Robots is a new UR+ application kit for companies of all sizes that simplifies the integration of autonomous bin picking of parts and accurate placement in machines using UR cobots.

ActiNav synchronously handles vision processing, collision-free motion planning, and autonomous real-time robot control, eliminating the complexity and risk usually associated with bin-picking and machine-tending applications.

The system is also incredibly easy to set up and program.

Today, most bin-picking products are solely focused on the vision aspect of bin picking and often require hundreds of lines of additional programming to bridge the gap from "pick" to "place" -- especially if the "place" is not just dropping into a box or tote but accurately inserting the part into a fixture for further processing.

ActiNav Autonomous Bin Picking changes all that, allowing manufacturers with limited or no bin-picking deployment expertise to quickly achieve high machine uptime and accurate part placement with few operator interventions.

Genius!

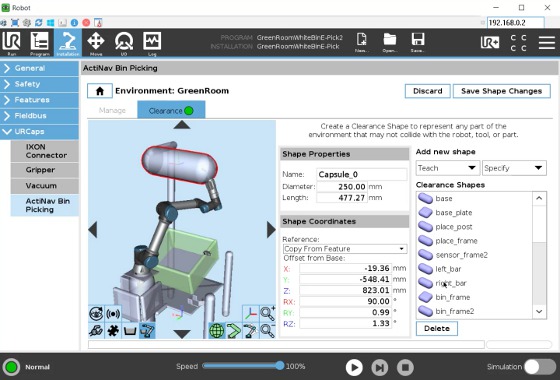

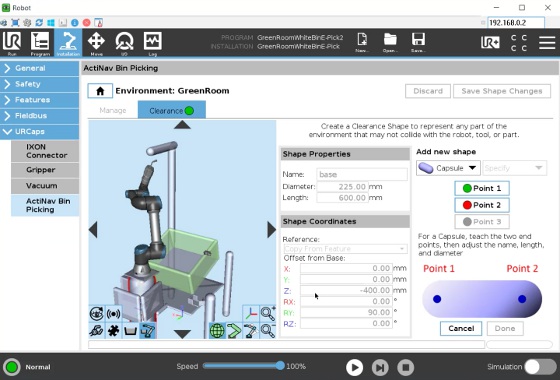

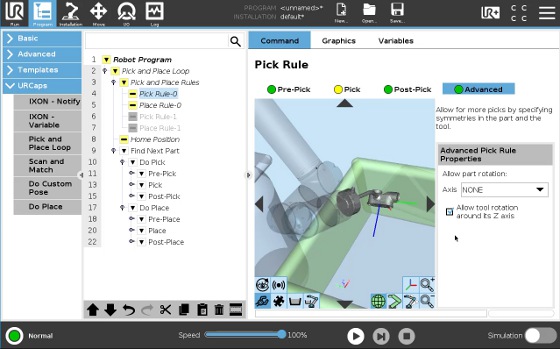

ActiNav combines real-time autonomous motion control, collaborative robotics, and vision and sensor systems in one easy-to-use, fast-to-deploy, and cost-effective kit. The system requires no vision or robotic programming expertise. Instead, it's based on a "teach-by-demonstration" principle using a six-step, wizard-guided set-up process integrated into the UR cobot teach pendant. ActiNav can be easily and quickly deployed by a manufacturer's in-house automation team or through assistance from a UR distributor or integrator.

ActiNav is available through UR's distribution channel and via the new UR+ Application Kits platform, an expansion of the cobot pioneer's successful UR+ ecosystem of components certified to work seamlessly with UR cobots. Like other UR+ application kits, ActiNav is developed with in-depth application knowledge that eliminates the duplication of engineering efforts when deploying widely used applications.

ActiNav works with UR's UR5e and UR10e e-Series cobots, a UR+ component or user-defined end effector, and an application-specific frame or fixture as needed. The kit includes the Autonomous Motion Module (AMM) and ActiNav URCap user interface software, along with a choice of 3D sensors. It is designed to handle part sizes from 1/2 in. to 5 in. Payload depends on the gripper and the robot arm used. The UR5e and UR10e can handle 11-lb and 22-lb payloads respectively. If the gripper chosen also supports this payload, that is what ActiNav can handle.

The ActiNav system includes the easy-to-use Teach Pendant that uses a simple "teach-by-demonstration" principle.

A six-step, wizard-guided set-up process is integrated into the UR cobot Teach Pendant to make programming fast, easy, and accurate -- even for final part orientation.

While there are lots of approaches to automating machine-tending stations, many of which include implementing trays, bowl feeders, or conveyors to get the parts to the machine, ActiNav bypasses this step. "Parts are often already in bins, so the most flexible and scalable option is to deliver that bin of parts to the machine and then pick them directly from the bin and place them into the machine," says Jim Lawton, VP of Product and Applications Management at Universal Robots. "This minimizes floor space and reduces the need for part-specific tooling."

ActiNav autonomously inserts parts into CNC or processing machines such as drilling, deburring, welding, trimming, or tapping. The high-resolution 3D laser sensor (structural light scanner) and CAD matching enables high-accuracy picks powered by ActiNav's Autonomous Motion Module (AMM) that determines how to pick the part, then controls the robot to pick the part and place it in a fixture -- correctly oriented -- each time. The autonomous motion control enables ActiNav to operate inside deep bins that hold more parts, something that standalone bin-picking vision systems struggle to accomplish.

The system runs about $100K, with a projected ROI of less than 18 months on a two-shift operation.

Universal Robots has a history of simplifying robotic technology. That's what their cobot business, the most successful in the world, is built on. ActiNav is the company's next step -- and an attempt to help manufacturers free up their labor pools from machine tending to do more impactful, and less tedious, work.

Learn more at www.universal-robots.com/actinav/.

Source: Universal Robots

Published April 2020

Rate this article

View our terms of use and privacy policy